QUALITY

All our processes are under the UNE-EN ISO 9001:2015 quality management standard. Thanks to normalised processes under our quality policy, and certified by internal and external audits, guaranteeing the homogeneity and high efficiency of our products.

CONTINUOUS IMPROVEMENT AS A FOUNDATION FOR THE QUALITY SYSTEM

The procedure established in our quality system, called Continuous Improvement, is meant to achieve greater efficiency and effectiveness in our production processes, and allows us to focus our strategy on improving the production processes of our customers.

On the basis of complaints of our customers, internal improvement proposals, indicator results, internal audits, and Non-Conformity cases, the Improvement Plan is deployed.

Establishing who will participate in the improvement, what indicators will measure the efficiency of the improvement, creating an action plan, and using management tools.

To finally achieve some improvements in internal procedures, which lead to patentable innovations at the product and manufacturing and assembly process levels.

Deployment of Quality Systems

QUALITY

The quality Department develops, deploys, and controls the procedures applicable to processes in order to guarantee compliance with all regulations established in ISO 9001:2015.

Administration

The procedures deployed in administration favor effective and efficient action in the management of invoices, shipment orders, and price control in relation with our customers and suppliers.

COMMERCIAL

Commercial management is fully integrated into the quality procedures, favoring a connection between the needs of our customers and the organisation’s knowledge of solutions to be developed.

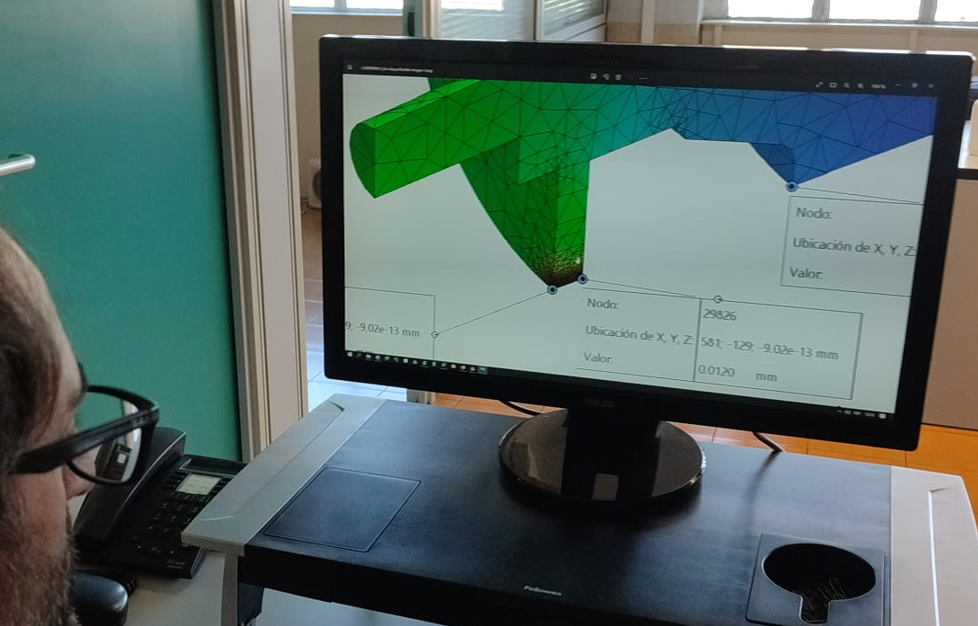

ENGINEERING

The procedures deployed in all phases of product development ensure a design aligned with the production process, guaranteeing the shortened technical specifications with the client, safety standards, validation plans; and all this under a document management system.

PURCHASE

Supplier management guarantees compliance with technical specifications through an approval process aimed at guaranteeing quality standards and meeting deadlines.

FABRICATION

Assembly

New projects or equipment received for maintenance are inspected and assembled completing and recording the final validation plans based on the technical specifications that are checked in our testing laboratory together with our customer.

Logistics

The procedures established in Logistics are focused on ensuring that the product arrives at its destination within the agreed term and in optimal conditions for its use by the customer.

SAT

SAT procedures allow for the tracking of resharpening and grinding service history, as well as the maintenance of equipment and supply or parts to any part of the world in an effective and efficient manner, disposing for this a permanent stock that can be agreed on with our customers. Our machines can be controlled remotely and establish predictive criteria on key factors for a more reliable solution.